High Expansion Foam Fire-fighting System

(for Machinery Space/Cargo Pump Room)

Introduction

In 1992, Kashiwa took the lead in the world in developing the high expansion foam fire-fighting system generating foam to extinguish fires in its protected areas, and started providing the system using air in a machinery space and cargo pump room for foam generation, which is safer and more efficient than any conventional systems.

Foam discharge test

Principle / Advantages

Inside air high expansion foam system extinguishes fires with cooling and smother effect of the foam. Foam solution, the mixture of seawater (or fresh water) and foam concentrate (foam liquid) mainly consisting of synthetic smother, is delivered to metallic foam generators to get aerated and turned into foam. The generated foam has significant fire resistance due to several stabilizers contained in the foam liquid, applicable to a wide range of fires, including oil fire with petrol, naphtha, heavy oil or light oil, and wood or cloth fire, and very safe to human bodies.

This system is highly regarded by ship owners who are keenly interested in safety and reduction of environmental impact as an ideal alternative to conventional CO2 system which poses health hazard to ships’ crew by inhalation, or Halon system using the gas that destroys Ozone layer.

System Configuration

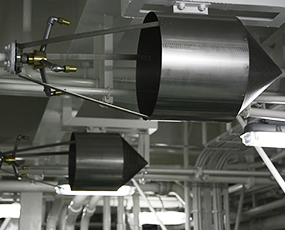

The system mainly consists of foam liquid tank, foam liquid pump, proportioner, manual/automatic valves, foam generators, and control panel.

Delivery Record

The system has been delivered to approximately 4,600 ships so far.

Introduction Movie

Main control panel

Foam liquid tank

Foam liquid tank unit

Foam generator

(horizontally arranged)

Foam generator

(vertically arranged)

Diaphragm valve